In many medical applications, intra-venous (IV) fluids and drugs need to be infused over a period of time, which could be several minutes, hours and days. The most common method of doing this is by manual injection doses using syringes by manually setting the drip rate of gravity-feed intra-venous infusion sets.

The application of infusion pumps continues to grow, extending to patient–controlled analgesia, home therapy, chemotherapy, implantable drug pumps (such as insulin delivery pumps) etc. For meeting the exacting requirements of these applications in terms of flow rate of the fluids in a safe and effective manner, the pumps are becoming smaller and smarter.

The volumetric infusion pump is generally used to deliver larger volumes of fluid (> 60 cc) from a bag or bottle. This pump technology evolved from the desire to improve on the flow rate control provided by the simple, mechanical roller clamp.

The first improvement was the electronic drop counter that could quickly determine the drip rate of IV delivery. Soon thereafter came a device which could control the drop rate automatically.

Infusion Pumps Application

In Hospital

The most common application of infusion pump is to maintain appropriate fluid levels in the patient. Fluid therapy is used in the management of patients during and after surgery, for treatment of burns, and in treating dehydration in paediatric patients. The therapy involves the controlled infusion of plasma expanders, usually at a rate determined by the patient’s fluid balance.

Continuous drug infusion is also used for such widely different applications as delivery anaesthetics during surgery, chemotherapy for cancer, and anti-arrhythmic drugs for patients in the coronary care unit.

Ambulatory Application

Wearable pumps have also been used for delivering agents that were previously used only in a hospital environment. Anti-cancer drugs can be continuously infused in ambulatory patients and recently devices have been developed that deliver pain suppressants under patient control.

The drug infusion systems basically consist of two components: a mechanism that delivers the drug, and a means of controlling the rate of delivery. In open loop systems the rate of delivery is set by the nurse or physician on the basis of past experience, mathematical computation, or by trial and error. The fluid is delivered at the set rate until the setting is changed. In closed loop systems, the effects of the drugs are monitored by appropriate transducers, and the desired delivery rate is computed and set automatically.

Syringe Pumps

In syringe pumps a motor, through a gear-reducing mechanism and a lead screw, applies force to the plunger of a syringe containing the drug. The device is mainly convenient for applications that require the delivery of volumes limited by the syringe size.

Syringe Pumps are particularly helpful under such circumstances as they are programmed to deliver drug through the vein at a determined rate.

Syringe pump consist of a drum that is attached to a piston.

The piston is operated by a motor through a drive screw gear which helps in pushing the plunger of syringe in or out the resulting in a smooth flow.

The syringe is engaged on a clamp on the frame and the plunger of the syringe is displaced by the movement of the drum.

Most of the syringe pump can work with different syringes of different diameters but the diameter has to be entered in the beginning to make sure the correct volume is dispensed.

Closed Loop Control in Infusion Pumps

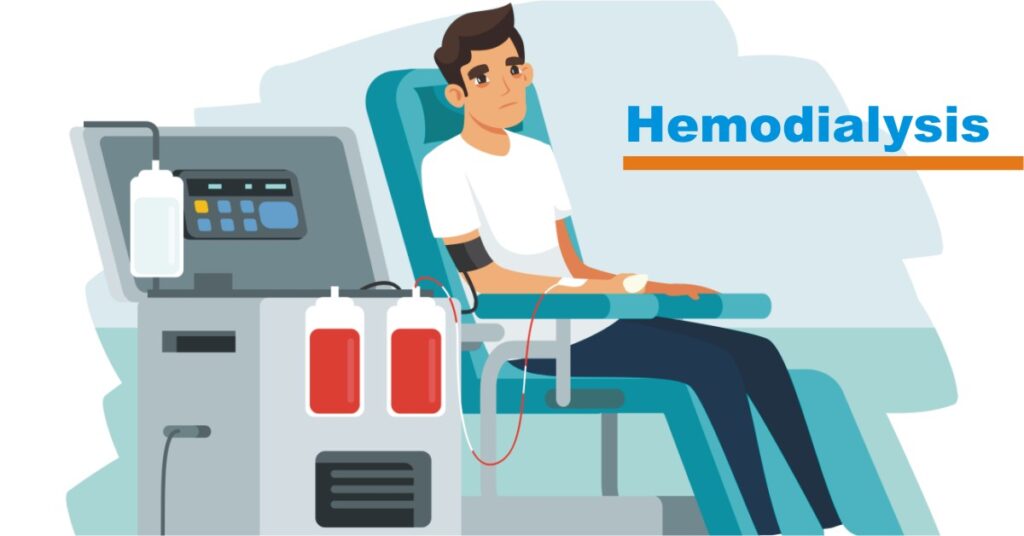

Closed-loop drug infusion pumps are among a growing number of systems designed to automate the control of physiological variables either in a clinical or laboratory setting.

There are two major reasons for automated closed-loop control. The first is to improve patient care by delivering the right amount of agent for maximum effectiveness.

The second reason for using automated closed-loop control is to reduce the cost of medical care. It takes almost undivided attention to manually control the infusion rate of some commonly used short-acting agents.

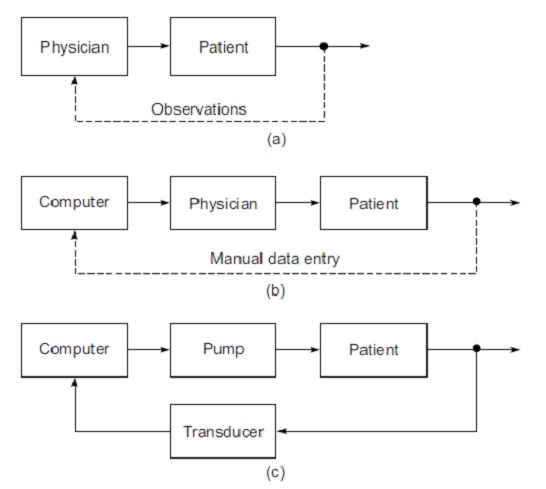

In traditional drug therapy the rate or amount of infusion is selected by the health professional on the basis of experience and observations made about the patient.

More recently, it has become possible to enhance the traditional mode of drug therapy by using a computer to advise the physician what the appropriate dosage should be.

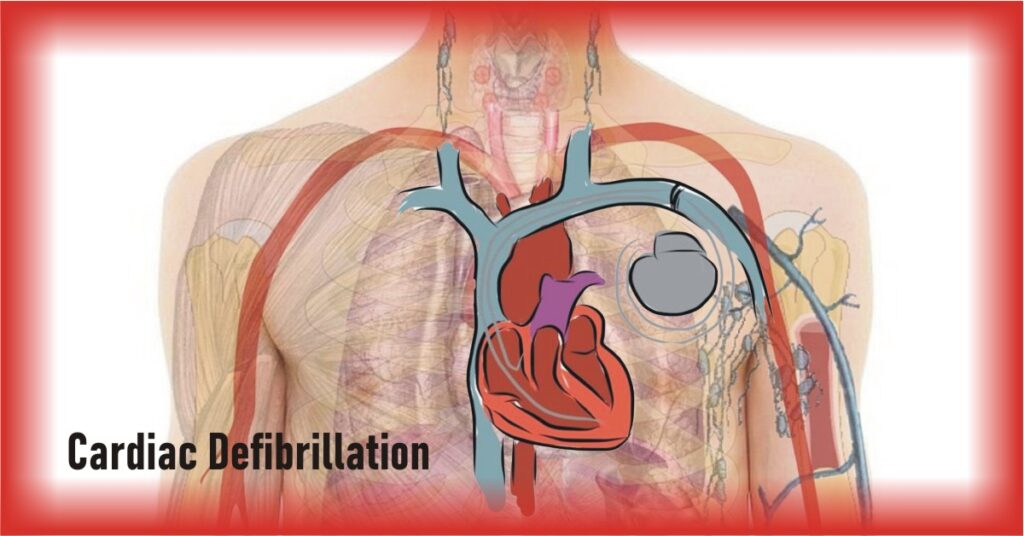

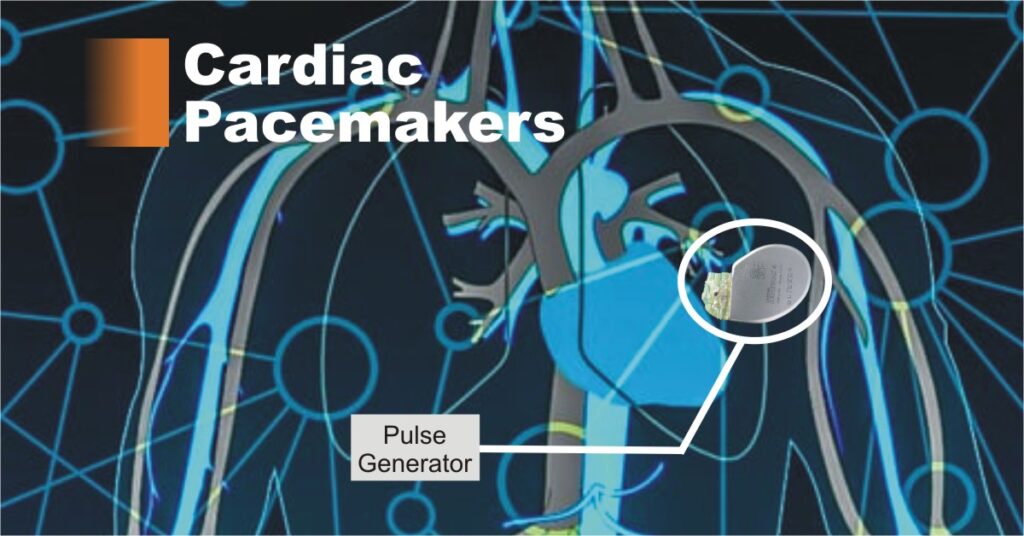

In a fully automated system the transducer senses the controlled variable, a computer algorithm determines the infusion rate on the basis of the discrepancy between actual and desired variables, and the computed infusion rate is automatically delivered by a pump.

Drop Rate Counter Type Infusion Pumps

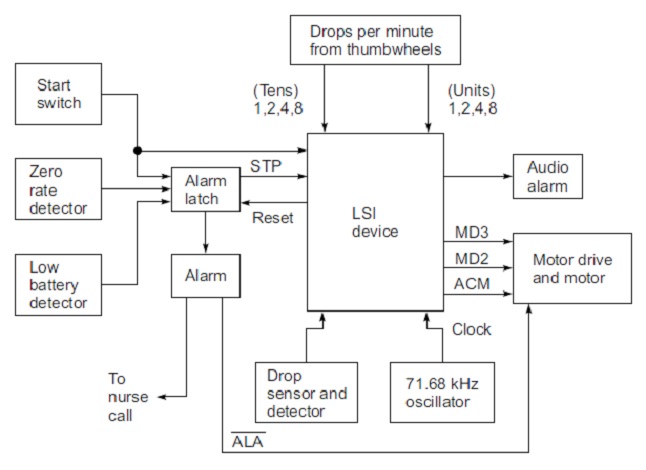

The device consists of three major components: the fluid reservoir, a catheter system for transferring fluids into the body and a device that combines electronics with a mechanism to generate and regulate flow. The heart of the system is a customized digital device which performs all the logic functions. It operates under the control of a clock frequency of 71.68 kHz obtained from a crystal controlled oscillator which provides various timing and control signals.

The drop sensor is attached to the administration set drip chamber and closes the servo loop by providing rate feedback information. The drop sensor contains an array of light emitting diodes (LEDs) and phototransistors which generate a signal each time a drop of IV fluid falls into the drip chamber.

The infusion of drugs requires high flow-rate accuracy and flow uniformity. Sensors can be used to count the number of drops passing through the drip chamber. Sensors can also provide flow feedback for automatic rate adjustment.

Programmable Volumetric Infusion Pumps

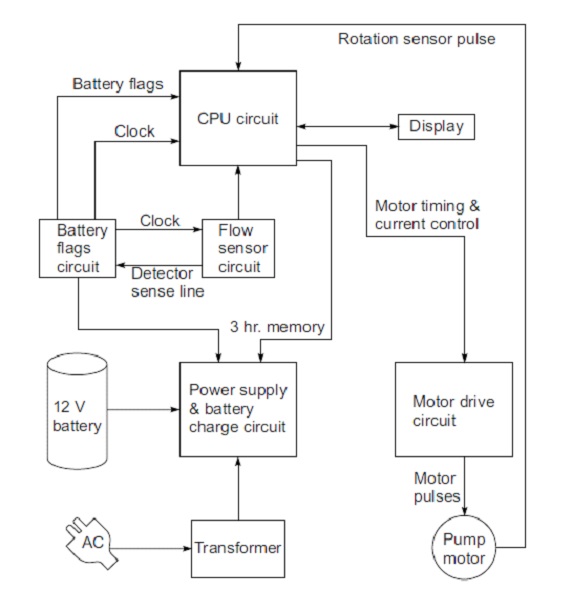

One alternative to the drop sensor is a volumetric metering chamber. A pump with a stepper or servo-controlled DC motor can be used to provide the driving force for the fluid by mechanized displacement of the contents in the volumetric chamber. The stepping resolution, along with chamber elasticity, can influence flow uniformity.

Volumetric implies flow rate calibration in units of known volume, ml/hr, rather than non-volumetric units of drops/minutes. It incorporates a peristaltic (tube squeezing) pump mechanism. The flow rate is calibrated on known inner diameter tubing. Flow rate is a function of pump speed, tubing inner diameter, and tubing elasticity. The speed of the pump is maintained electronically within ± 0.1%.

ALSO READ

Blog Image by xb100 on Freepik