Preface

Medical 3D printing, also known as additive manufacturing in the healthcare sector, has surfaced as a transformative technology with the capability to transform patient care and medical practice. This invention allows healthcare professionals to produce highly accurate and customized 3D models, implants, prosthetics, and even human tissues and organs. In this article, we explore the exciting world of medical 3D printing, its diverse operations, and the profound impact it has on the future of healthcare.

Understanding Medical 3D Printing

Medical 3D printing is an advanced application of additive manufacturing that involves the creation of intricate three- dimensional objects with biocompatible materials. The technology utilizes digital imaging and computer- aided design( CAD) to create detailed models of anatomical structures or medical devices, which are also fabricated layer by layer using many materials, similar as plastics, metals, and even living cells.

Applications of Medical 3D Printing

Personalized Medicine

Medical 3D printing has steered in a new period of personalized medicine, wherein patient-specific models are created to tailor treatments and interventions uniquely to each individual. These models enable healthcare professionals to gain deeper perceptivity into a patient’s condition, enhancing diagnostic accuracy and treatment planning.

Surgical Planning

Surgeons are increasingly using 3D- printed anatomical models to practice and upgrade complex surgical procedures. The models give an accurate representation of a patient’s anatomy, allowing for better preoperative preparation, reduced surgical time, and enhanced surgical results.

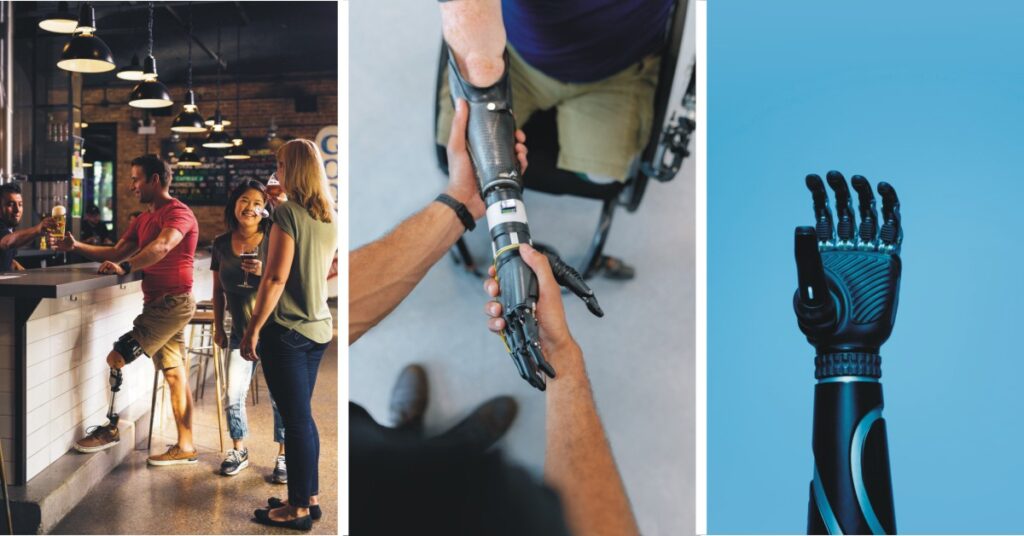

Medical Devices and Prosthetics

3D printing has revolutionized the production of medical devices and prosthetics. custom-made implants and prosthetic limbs can now be fabricated with ameliorated fit and functionality, enhancing patients’ quality of life and mobility.

Regenerative Medicine and Tissue Engineering

Biomedical engineers are making significant strides in the field of regenerative medicine by using 3D printing to produce biocompatible scaffolds and structures for tissue engineering. These engineered tissues show pledge in repairing and replacing damaged organs and tissues.

Anatomical Education and Training Medical

3D printing has transformed medical education, offering scholars and healthcare professionals access to palpable and accurate anatomical models. This hands- on approach enhances learning experiences and refines surgical experience.

Advantages of Medical 3D Printing

Precision and Accuracy

Medical 3D printing allows for the creation of much accurate and intricate models, reducing errors and enhancing patient outcomes.

Cost effectiveness

Customized medical devices and implants can be produced much cost- effectively with 3D printing, compared to traditional manufacturing styles.

Reduced Surgical Risks

Preoperative planning with 3D- printed models helps surgeons identify possible challenges and complications before entering the operating room, minimizing surgical risks.

Enhanced Patient Communication

Three- dimensional models enable healthcare providers to communicate complex medical conditions and treatment plans more effectively to patients, leading to enhanced patient understanding and engagement in their care.

Challenges and Future Outlook

While medical 3D printing holds immense pledge, several challenges must be addressed to completely realize its capability. Some of these challenges include

Regulatory Compliance

As medical 3D printing becomes more widespread, regulatory frameworks must keep pace to ensure patient safety and product quality.

Material Biocompatibility

The development of biocompatible and bioresorbable materials for 3D printing is critical to advancing the field of regenerative medicine and tissue engineering.

Integration into Healthcare Systems

Implementing medical 3D printing into existing healthcare systems requires training, resources, and flawless integration with medical workflows.

FDA Approval procedure for Bioprinting

Acquiring FDA approval for medical 3D printing involves navigating through a rigorous regulatory process to ensure patient safety and product efficiency. The Food and Drug Administration( FDA) in the United States regulates medical devices, including those produced using 3D printing technology. Here’s an overview of the general procedure to get FDA approval for medical 3D printing

Determine Regulatory Pathway

Identify the appropriate regulatory pathway for your 3D- printed medical device. The FDA offers different pathways grounded on device category, intended use, and risk level. Devices can be classified as Class I( low risk), Class II( moderate risk), or Class III( high risk).

Preclinical Testing and Validation

Conduct preclinical testing and validation studies to demonstrate the safety and effectiveness of your 3D- printed medical device. This may include biocompatibility testing, mechanical testing, and performance evaluations.

Quality Management System (QMS)

Establish a comprehensive Quality Management System (QMS) that complies with FDA requirements, similar as ISO 13485. The QMS should cover design controls, risk management, manufacturing processes, and post-market surveillance.

Investigational Device Exemption (IDE) or 510 (k)Pre-Market Notification

For Class III devices, you may need to submit an Investigational Device Exemption (IDE) application to conduct clinical trials. For Class II bias, a 510 (k)pre-market notification may be needed to demonstrate substantial equivalence to a legally retailed predicate device.

Pre-market Approval (PMA) or De Novo Classification

For Class III devices and some Class II devices that aren’t mainly equivalent to any predicate, aPre-market Approval( PMA) application or a De Novo classification request may be necessary.

FDA Submission

Prepare and submit the appropriate application or notification to the FDA, including all relative data, test results, and documentation needed for the chosen regulatory pathway.

FDA Review and Feedback

The FDA will review the submitted application and give feedback. The review process may involve several rounds of questions, clarifications, and requests for further information.

Clinical Trials (if applicable)

However, ensure compliance with Good Clinical Practice (GCP) guidelines and attain Institutional Review Board (IRB) approval, If conducting clinical trials under an IDE.

Post-market Surveillance

Implement a post-market surveillance plan to cover the safety and performance of your 3D- printed medical device after it enters the market.

FDA Approval or Clearance

Upon successful completion of the FDA review process and meeting all requirements, you’ll receive FDA approval (PMA) or clearance (510 (k) or De Novo), allowing you to market your medical 3D- printed device.

It’s important to note that the FDA regulatory process can be complex and time- consuming. Engaging with regulatory experts and consultants can help streamline the process and increase the chances of a successful FDA approval for your medical 3D printing device. Additionally, regulations and requirements may vary in different countries, so be sure to research and check with relevant international regulations if you plan to market your device widely.

Visit FDA for 3D Printing of Medical Devices HERE

Conclusion

Medical 3D printing represents a transformative force in ultramodern healthcare, empowering medical professionals with unparalleled tools to help patient care and results. From personalized medicine to regenerative therapeutics, the uses of 3D printing in drug are vast and diverse. As technology continues to advance and researchers innovate innovative approaches, the capability for medical 3D printing to save lives, enhance patient experiences, and revolutionize healthcare is limitless. It’s clear that this groundbreaking technology will continue to shape the future of medicine, leading in a new period of precision, customization, and compassion in patient care.

You May Be Interested In